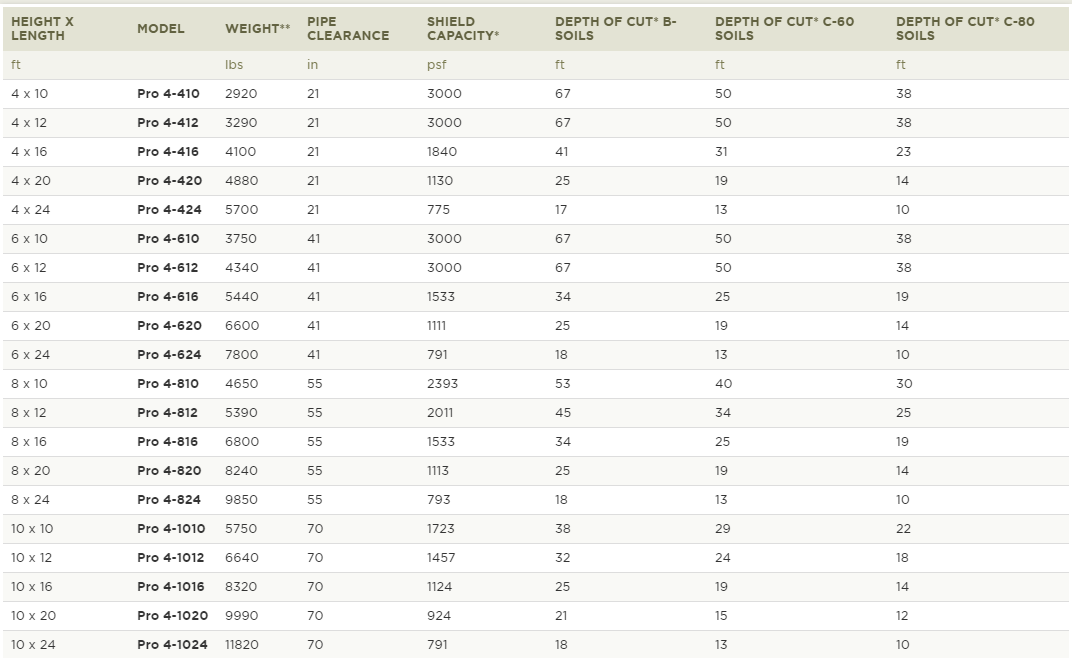

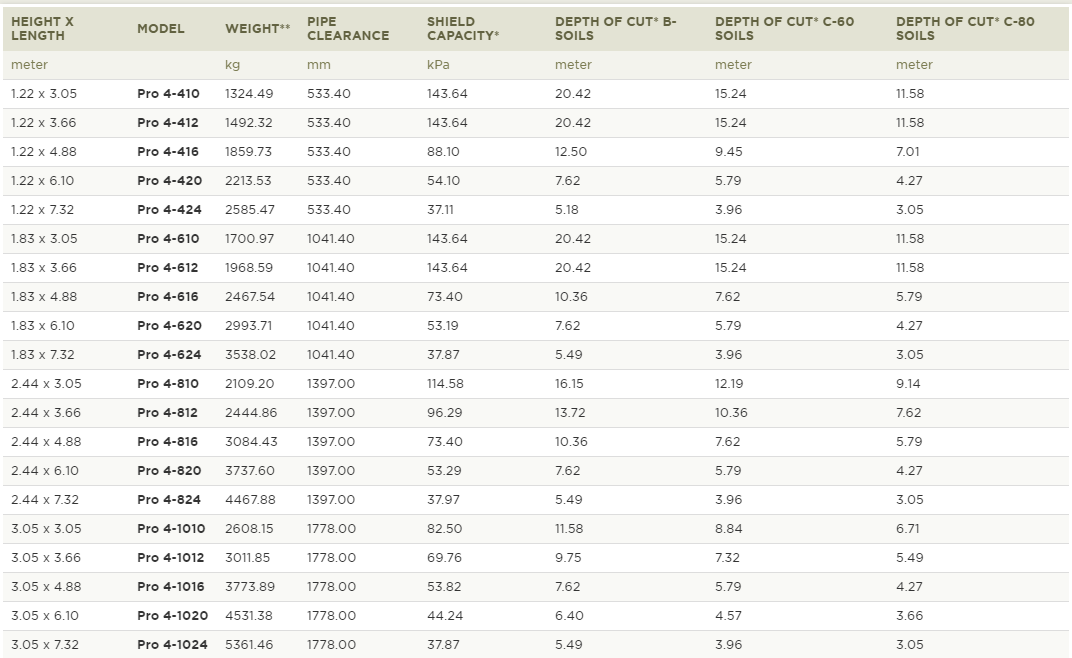

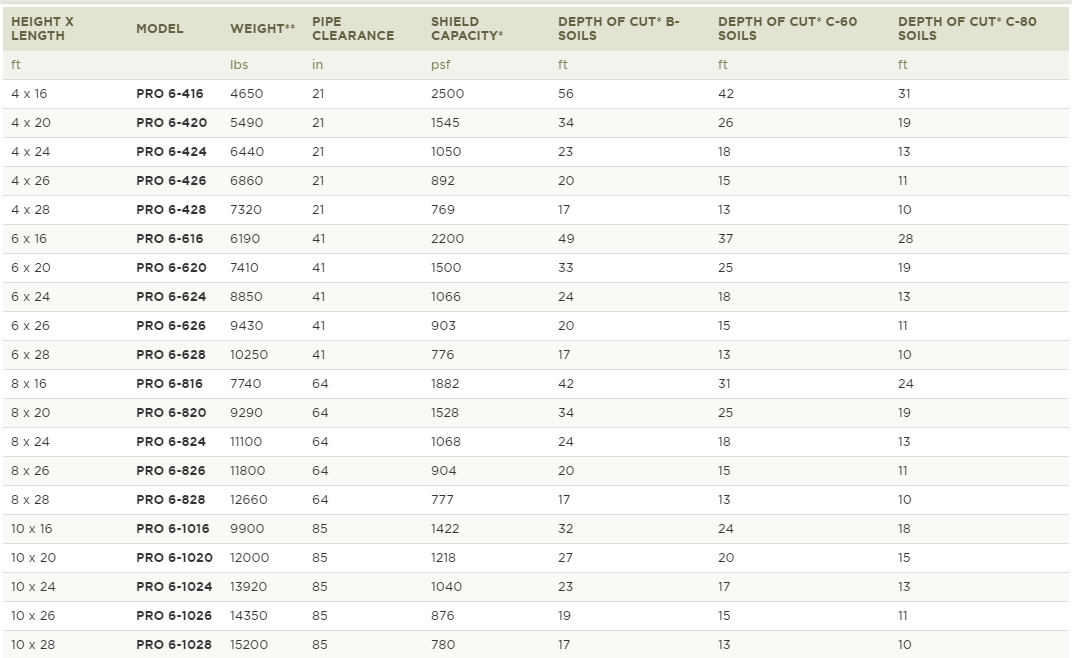

To determine the right size of trench shield for your job, there are a series of questions you have to answer. Here are the main ones. Answer them, consult the tables and information which accompany our specific products, and always refer to manufacturer’s serialized specific tabulated data* and all applicable safety standards prior to each use.

What kind of job is it?

E.g., sewer, repair, water main, manhole, pump station, bore pit, etc.

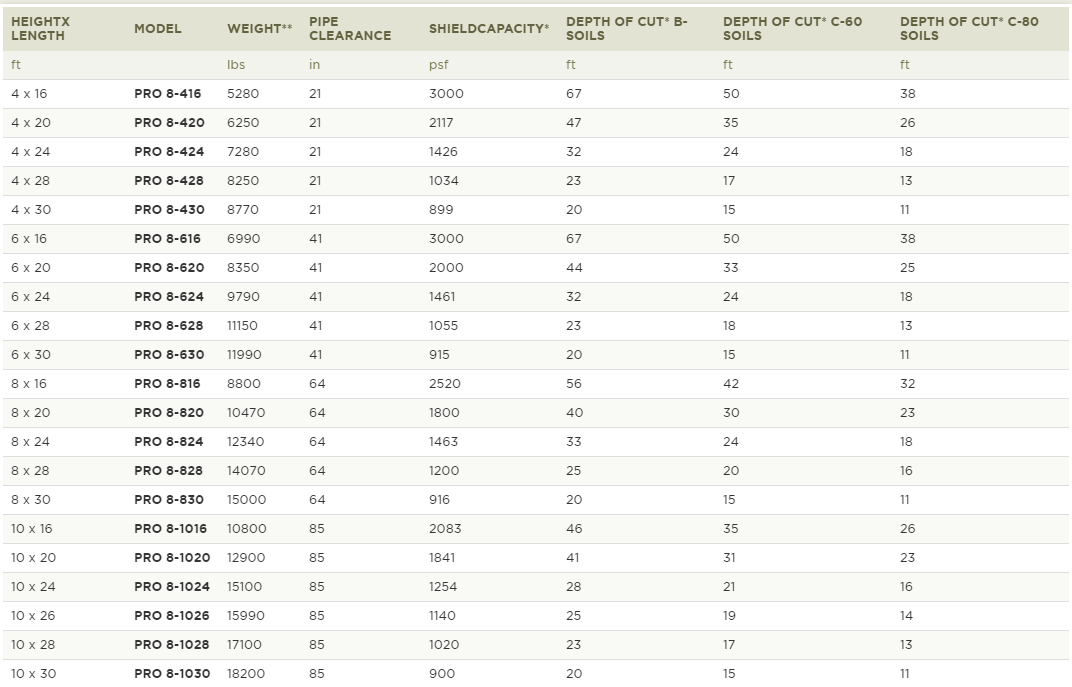

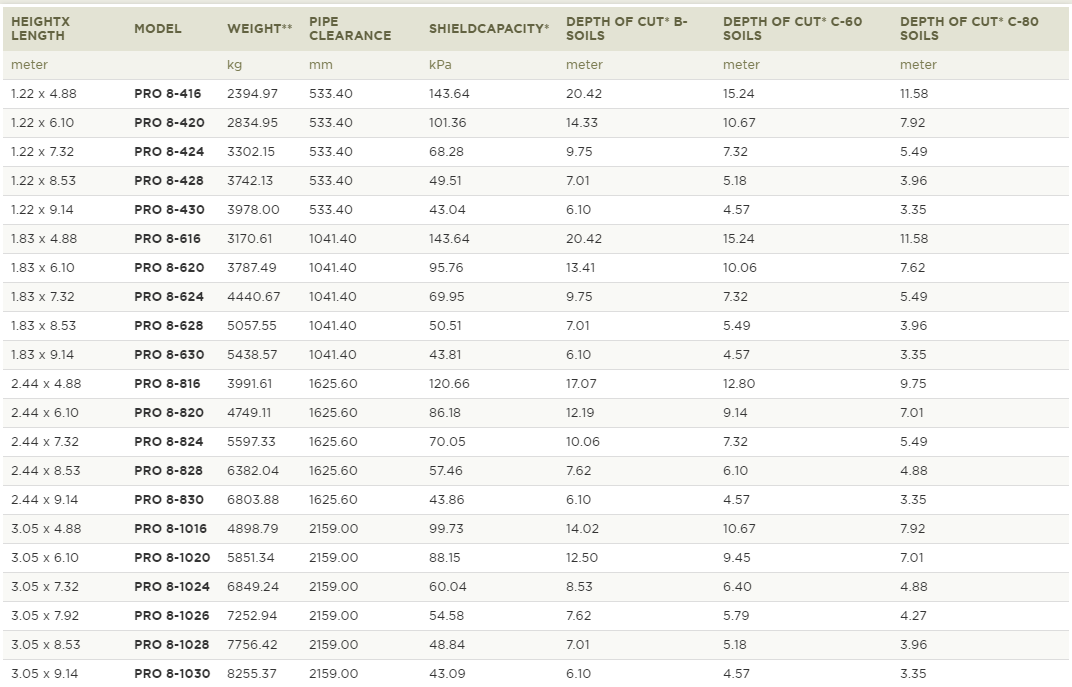

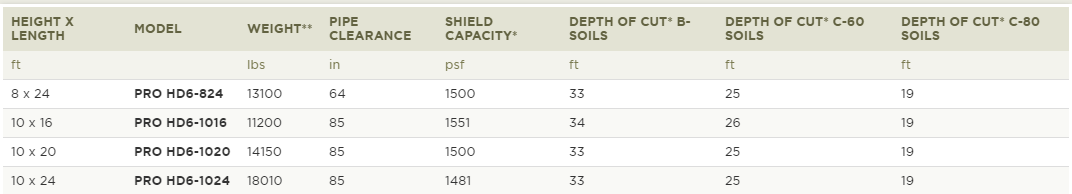

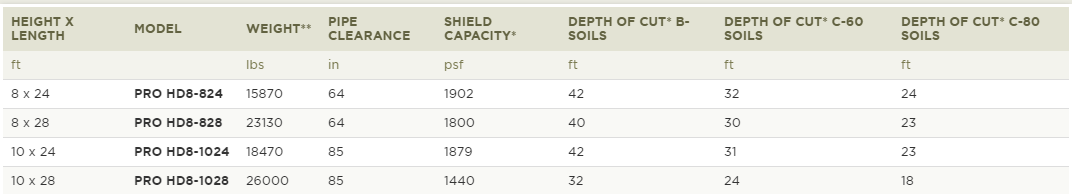

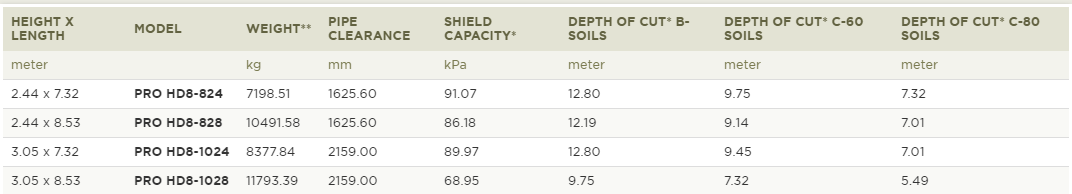

Depth of cut?

Soil conditions?

B-soils (45 lbs per foot of pressure)

C-60 soils (60 lbs per foot of pressure)

C-80 soils (80 lbs per foot of pressure)

Hydrostatic

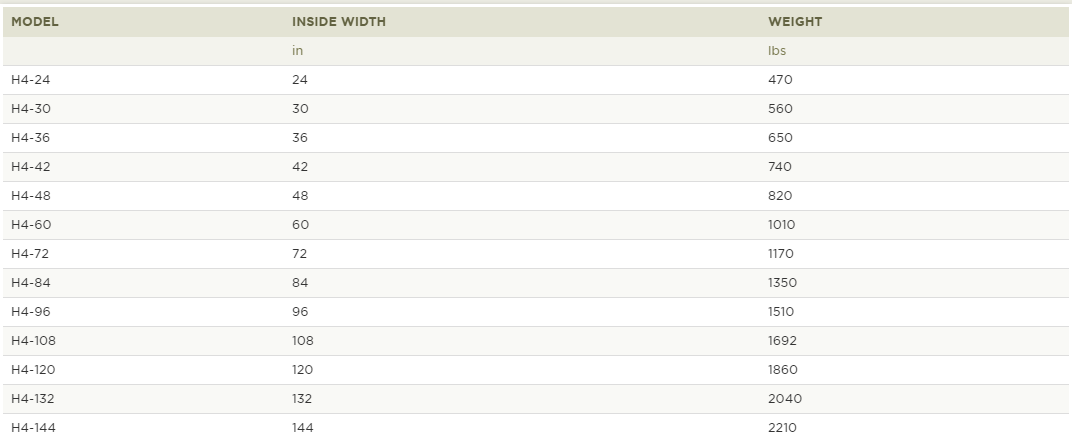

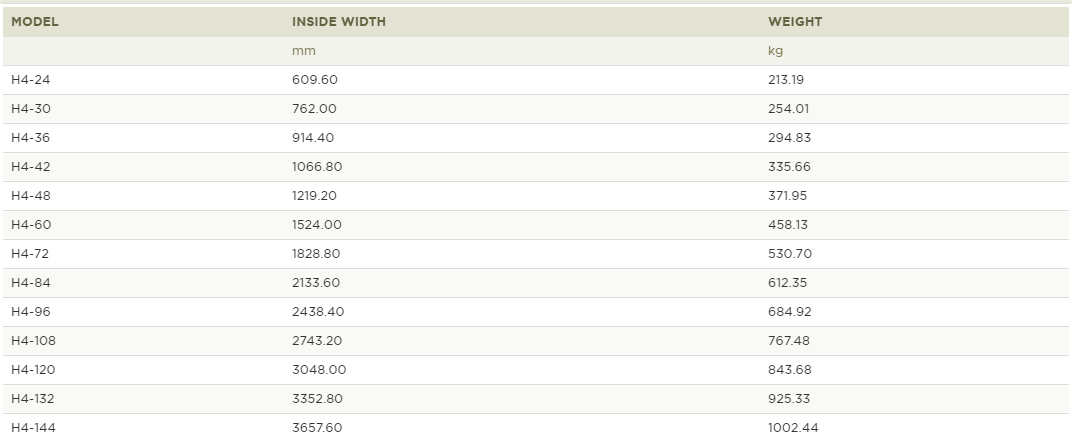

FIGURING OUT SPREADER LENGTH

If working with pipe, what is the outside diameter of the pipe? (It is recommended that the trench shield be at least 12” wider than the pipe)

What is the width of the bucket, including any side cutters? (It is recommended that the trench shield be at least 12” wider than the bucket)

FIGURING OUT TRENCH SHIELD LENGTH

If working with pipe, what is the length of the pipe sections? (It is recommended that the trench shield be 2’ – 4’ longer than the pipe)

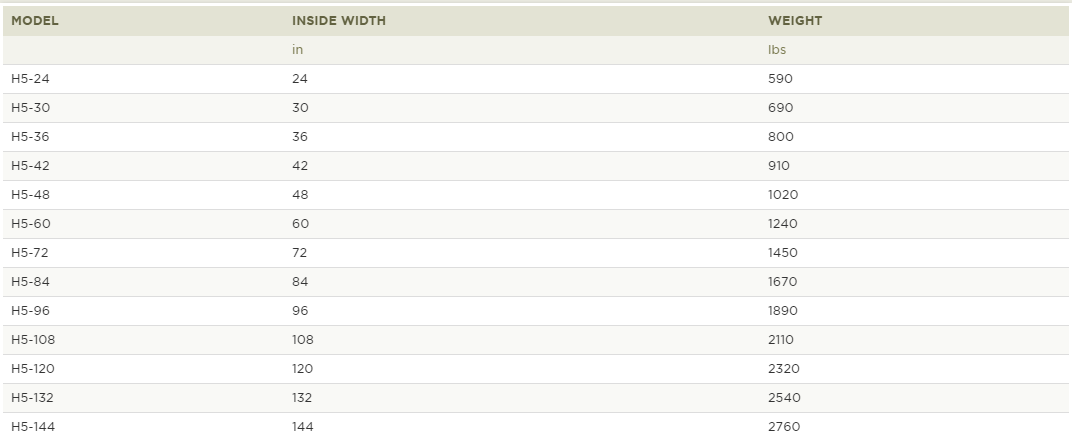

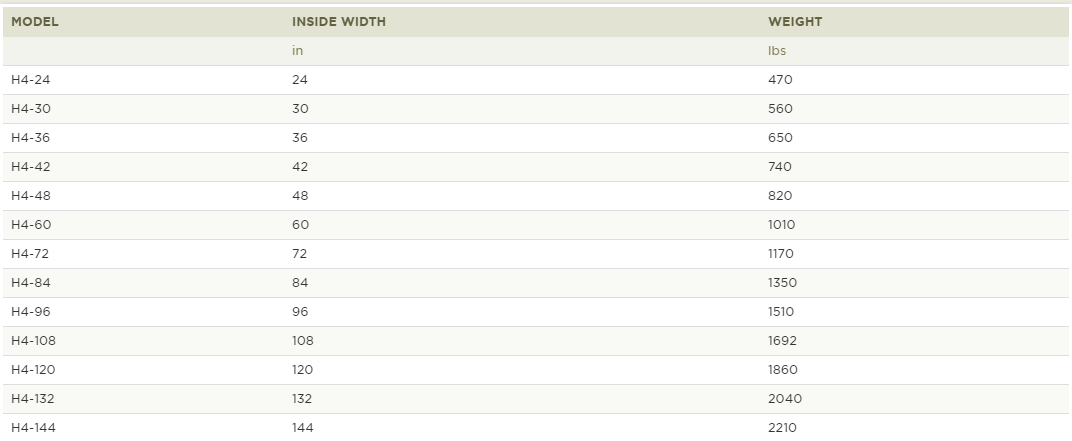

FIGURING OUT MAXIMUM WEIGHT OF TRENCH SHIELD SYSTEM

Take the working weight of the machine that is going to be used at the job site and divide it by 5. That will give you the maximum weight your machine can handle for a trench shield (including spreaders).

Example:

Cat 336E L has an operating weight of 86,200 lbs. 86200/5 = 17240. A trench shield with spreader pipe would need to weigh less than 17,240 pounds to be used with this excavator.