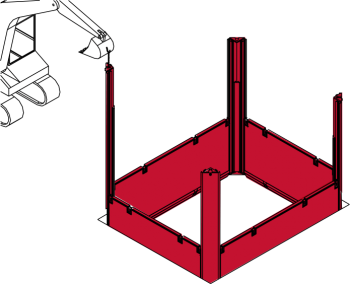

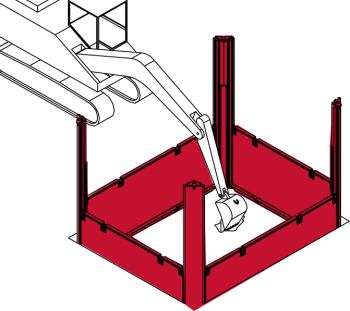

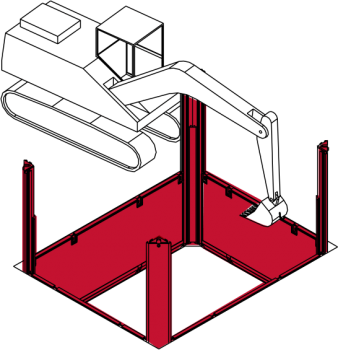

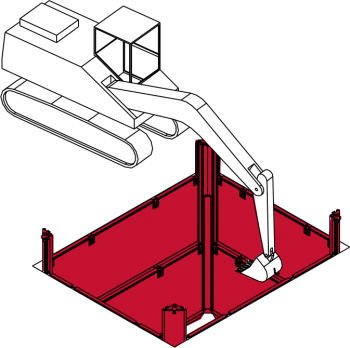

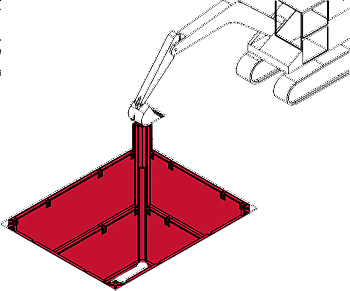

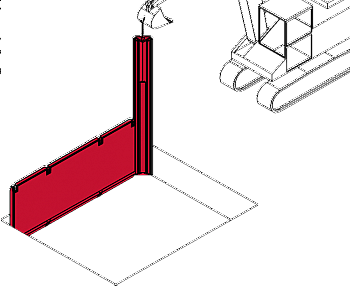

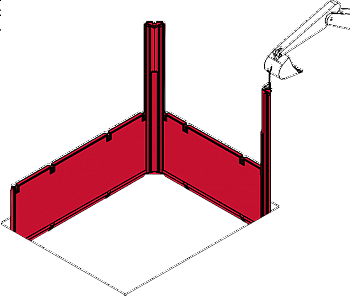

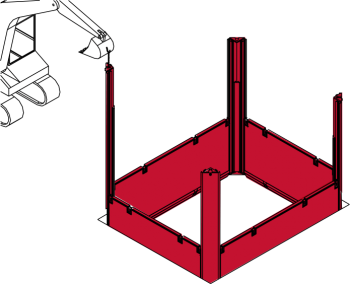

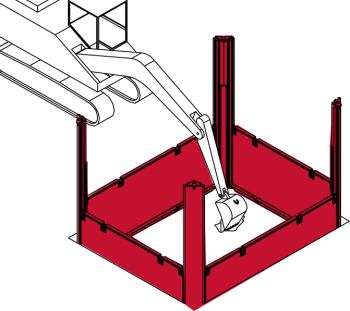

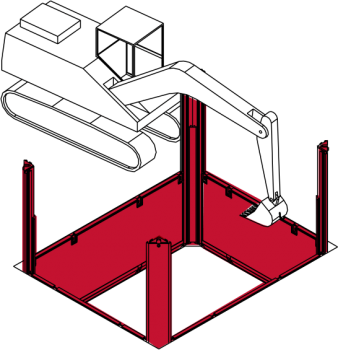

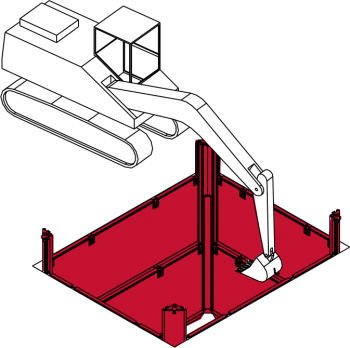

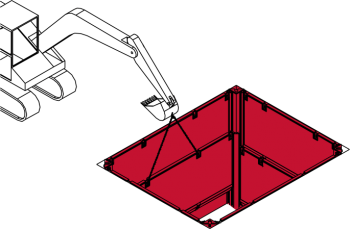

Installation

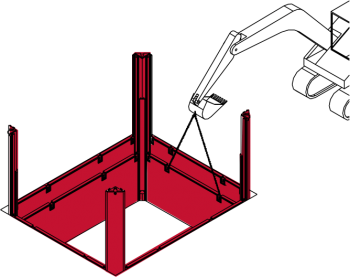

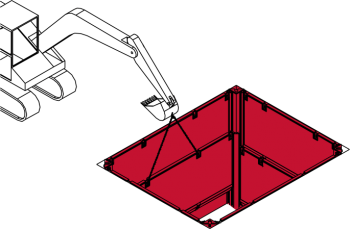

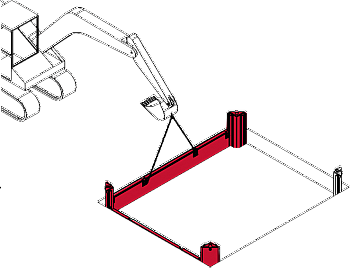

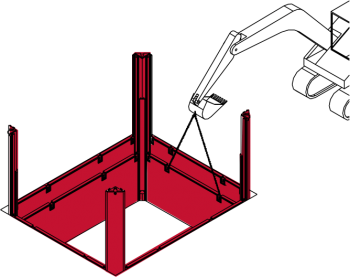

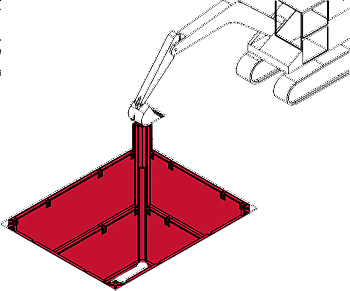

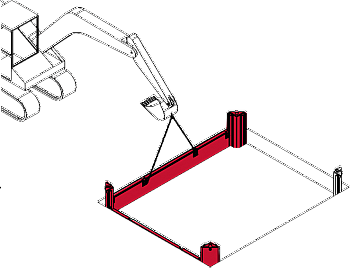

Removal

The Pro-Tec Equipment Slide Rail System is a dig-and-push style trench shoring system. With its modular, flexible design the system can work with a wide variety of shapes and sizes. The Pro-Tec Equipment Slide Rail Shoring System is installed from the top down and removed from the bottom up, minimizing size of excavations, soil disturbances and restoration time and cost. The installation is done with low vibration, providing soil support for excavations, adjacent structures and existing utilities.

When Should You Use Slide Rail?

• Bad soil conditions

• Lift/pump station installations

• Tight quarters

• Fuel tank installations

• C.I.P. foundations and footings

• Boring and receiving pits

Slide Rail Shoring Panels:

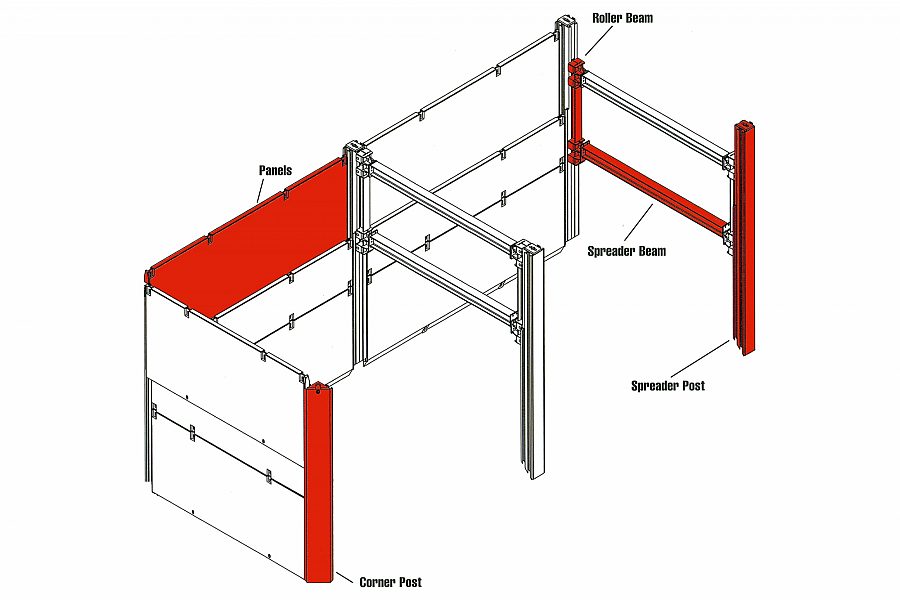

These panels are produced with the same quality as our trench shield panels. The slide rail shoring panels are reinforced along key stress points to ensure a long service life and continued use. They are a smooth wall design which reduces friction during the removal process. Each panel features the industry’s strongest and only one-piece t-lock design, which eliminates welds, reduces friction and provides a secure connection at the most critical point of the slide rail shoring system.

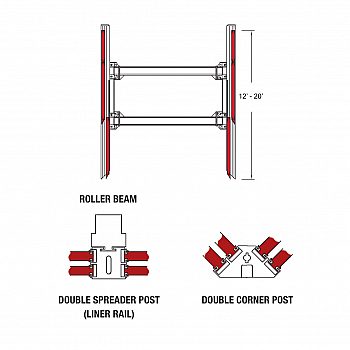

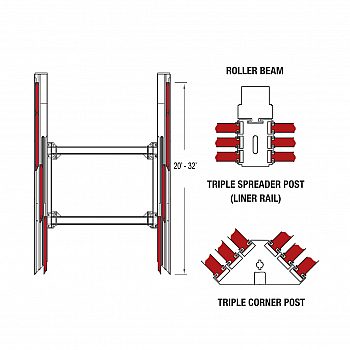

Slide Rail Corner Posts:

Available in Single (8’-12’ in depth), Double (16’ – 20’) and Triple (24’ – 28’). The Slide Rail Corner Posts are used at the corners of the excavation. Each post features a reinforced cutting edge (bottom) to “knife” into the soil, heavy-duty push plate (top) to hold up to excavator buckets, track cutouts to reduce the height need to lift the Slide Rail Shoring Panels, and the industry’s first quick release (ground release) shackle connection that eliminates the need for a worker to climb a ladder to remove the installation rigging. All of these features allow for a quicker and more efficient installation.

Generation II Post (Gen II) are available for use in systems ranging from 12′ to 24′ in depth. These Gen II post feature a combination of the tight track design and a more open, slot track design for the inner track. This unique combination enables Pro-Tec Equipment Slide Rail Systems to achieve 20′ deep clearspan systems without having to use larger, heavier posts.

Slide Rail Spreader Posts (a.k.a. Linear Rails):

Available in Single (8’-12’ in depth), Double (16’ – 20’) and Triple (24’ – 28’). The Slide Rail Spreader Posts (a.k.a. Linear Rails) are used at for linear and multiple bay applications. Each post features a reinforced cutting edge (bottom) to “knife” into the soil, heavy-duty push plate (top) to hold up to excavator buckets, track cut outs to reduce the height need to lift the Slide Rail Shoring Panels and the industry’s first quick release (ground release) shackle connection that eliminates the need for a worker to climb a ladder to remove the installation rigging. All of these features allow for a quicker and efficient installation.

Generation II Post (Gen II) are available for use in systems ranging from 12′ to 24′ in depth. These Gen II post feature a combination of the tight track design and a more open, slot track design for the inner track. This unique combination enables Pro-Tec Equipment Slide Rail Systems to achieve 20′ deep clearspan systems without having to use larger, heavier posts.

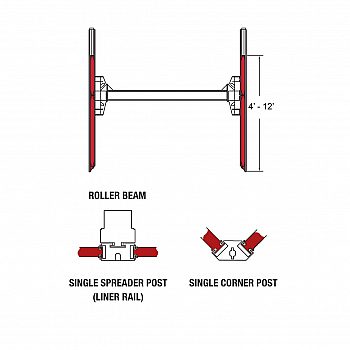

Slide Rail Roller Beams:

Available in Single (to be used with Single Spreader Post (a.k.a. Linear Rails), Double, Double Box Beam (to be used with the Double Spreader Post) and Triple. These roller beams attach to the inside face of the Slide Rail Spreader Post (a.k.a. Linear Rails), keeping these posts parallel and allowing vertical movement to accommodate maximum vertical clearance. All Slide Rail Roller Beams include heavy duty 4” diameter steel wheels with the industry’s only grease zerk fitting to easily grease the wheels, allowing them to effortlessly move up and down the Slide Rail Spreader Posts.

Slide Rail Spreader Beams:

The Slide Rail Spreader Beams are designed to attach to the Roller Beams, creating a rolling cart system. These beams are modular, meaning that beams can be added to or removed from the system to obtain the desired internal width of the system. The Slide Rail Spreader Beams are constructed for W12 x 106 beam, which provide a sturdy, rigid frame that won’t bind or rack when the rolling cart system is being moved.

The Double Box Beam spreader beams are constructed of high-strength steel, welded to take the shape of a box. These beams, when used with the Double Box Beam Roller, provide an increased vertical clearance inside the excavation.

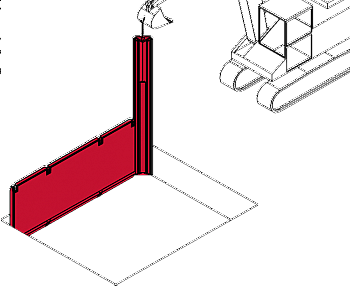

Single Slide Rail System

Designed to be used for smaller, shallow excavations, such as fuel tanks, building footing and linear pipeline work, the single slide rail system provides protection at a depth range of 4’ to 12’. All panels sit in a single track, enabling the removal of panels in a single lift, making it an ideal system for 60,000 to 80,000 lb. machines.

Double Slide Rail System

The most popular of the slide rail systems, the double slide rail system provides protection at a depth range of 12’ to 20’. This system was designed to be used with 80,000 to 100,000 lb. machines, on jobs ranging from manhole installations to lift stations to soil remediations and anything inbetween.

Triple Slide Rail System

The triple slide rail system, providing protection at a depth range of 20’-32’, is ideal for any application requiring a deep cut. Designed to be used with 100,000-plus lb. machines, the triple slide rail system can be used on any job on which a slide rail system can be used.

The only thing that is inside this system is the structure or tank that you need to put in. When using Pro-Tec Equipment’s Slide Rail Shoring System in a Clearspan application, you don’t have to worry about any internal walers taking up precious space, causing the outside dimension of the excavation to be larger than need be.

Pro-Tec Equipment’s Clearspan consists of external walers and tiebacks, along with a sacrificial beam, located at the bottom of the excavation. Our system is designed with the knowledge that time is critical and the cost of excessive, unneeded backfill is something every contractor can do without.

Pro-Tec Equipment can provide a Clearspan setup for all three of our systems (Single, Double and Triple track), enabling greater flexibility to meet the demands and needs of your particular job requirements.

For example, the accompanying picture shows a project measuring 12’ deep x 12’ wide x 69’ long (using 4 bays of 16’ panels). The project involved multiple fuel tanks being installed at Detroit Metro Airport with the aid of a PC 600 Komatsu excavator.

When using Pro-Tec Equipment’s Slide Rail Shoring System for boring applications, we are able to provide 20’+ clear space in the first bay, large enough to accommodate your casing size, while providing enough vertical clearance (typically 6′ – 8′) and space in the second bay for your machine. This provides you and your crew with a safe and economically viable work space.

Using the Utility Panel Guide in bore pit applications, the concern of material around the casing flowing into the excavation is removed. The Utility Panel Guide provides a safe, pre-engineered way to close off the front end of your pit.

With Pro-Tec Equipment’s versatile Slide Rail Shoring System, any of our systems (Single, Double and Triple) can be configured in a linear application. Configuring a Pro-Tec Slide Rail System for a Linear Application permits the use of longer pipe during installation, by simply raising and lowering the Roller Frame system. Using Pro-Tec’s Slide Rail System in a Linear Application has proven to be a great way to increase job site safety along with saving time and money.

For example, the picture shows more than 600,000 pounds of slide rail equipment on this job. A 24’ deep x 18’ wide x 146’ long system was used to find and repair pipeline in the Louisiana marshlands.

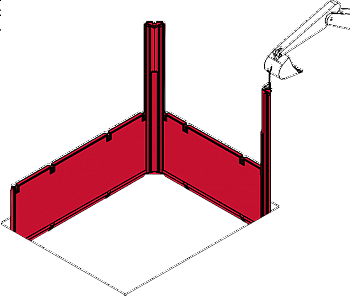

The most popular application for Pro-Tec Equipment’s Slide Rail Shoring System. Whether it’s a Single, Double or Triple System, Clearspan, Bore Pit or Linear Application, Pro-Tec Equipment’s 4-Sided Application provides complete protection on all sides when completely installed.

For example, in the picture, using a Komatsu PC 300, this double slide rail system, measuring 20’ deep x 10’ wide x 18’ long was installed in the middle of an active parking lot, allowing the crew to install an 8.5’ O.D. lift station.

SLIDE RAIL PANEL PULLER

The Pro-Tec Equipment Panel Puller is a 90-Ton Hydraulic Slide Rail Panel Extraction system. Designed to enable either direct connection to an excavators auxiliary hydraulic system or an external power pack that provides 5,000 psi to enablemaximum pulling force, the Panel Puller delivers enough force to extract Slide Rail Panels.

Using a 4.9” (125mm) diameter piston, and the ability to apply upwards of 89,900 lbf (400kN) of lifting force, the Panel Puller slowly and steadily lifts slide rail panels.

The Pro-Tec Equipment Panel Puller provides enough force to pull a slide rail panel to an easily accessible extraction point. Designed with a 3’3” (1m) stroke, and multiple strap connections, the Panel Puller is able to achieve this through multiple lifts, while sitting on top of the excavation. Additionally, the Panel Puller has the ability to provide site access relief on job-sites where access is an issue. With a smaller footprint than an excavator, the Panel Puller can be used to extract panels in the tightest of job-sites.